Impacting the benchmark defined in ETS

The route to a climate-neutral future runs in stages. Project ONE is already making a fundamental difference by making maximum use of the very best of what today’s technology offers. If we compare the Project ONE ethane cracker with all other European crackers (there are about forty) within the European Emission Trading System (ETS), we see that we are literally shifting the standard. In the steam crackers category, Project ONE emits 0.29 tonnes of CO2 per tonne of product, putting it at 43% of the benchmark (0.68 tonnes). That benchmark is determined by the 10% best performing plants. Once our ethane cracker goes online, it will significantly lower the benchmark, which will encourage other players to make additional sustainable investments or they will have to pay more for emission rights. Eventually it will displace older and less efficient production.

How will we achieve this reduction? How will we achieve this reduction?

CHOOSING ETHANE FOR OPTIMUM FEEDSTOCK CONVERSION

Ethane is much more “selective” for ethylene than naphtha, a crude oil distillate that is the dominant feedstock of steam crackers today. The difference is remarkable: if you crack ethane, about 76% is converted into ethylene; for naphtha, this is only 30%. This means that much more naphtha is needed to produce the same volume of ethylene. The cracking of ethane also produces more hydrogen than naphtha. This makes ethane the best possible feedstock for the production of ethylene.

USING HYDROGEN AS FUEL

The conversion reaction from ethane to ethylene releases more than 100,000 tonnes of hydrogen per year, which we use as an environmentally friendly fuel for the cracking ovens and steam generators. This significantly reduces our footprint. The combustion of hydrogen namely does not release any carbon.

MAXIMUM ENERGY EFFICIENCY

We design and strive for optimal integration: the low temperature of the feedstocks and the high temperature of the furnaces of the cracker are used elsewhere to save energy.

GREEN ENERGY

Project ONE’s purchased electricity use is fully met by renewable energy, for which we have concluded two large wind power contracts with Engie and RWE.

Customers supplied with ethylene from Project ONE can thus reduce their CO2 emissions by 2 million tonnes per year because they will no longer be dependent on ethylene from more polluting plants.

All options open for a climate-neutral future

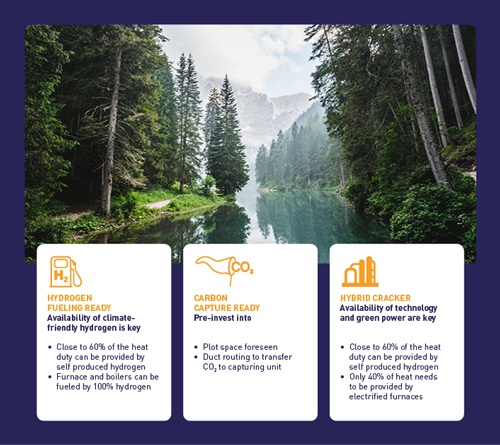

Due to its strong starting position, Project ONE will be best positioned to move towards a zero footprint. We have already incorporated the necessary flexibility into our plants to integrate other technologies as soon as they are mature and financially feasible. This allows us to reduce our footprint further. For example, it is technologically possible to feed the cracking furnaces and steam generators of Project ONE entirely with hydrogen, provided that enough climate-friendly hydrogen is available. With the investments currently being made in hydrogen technology and renewable energy, including in Flanders, it looks like this will be possible in future. Our design also already incorporates investments to set up a carbon capture installation, so that this option can also be utilised in the long term.

Today, electrification of a steam cracker is still on the distant horizon. Once this technology becomes industrially scalable and enough green power is available, our installation can take advantage of this as well. Thanks to the large quantity of hydrogen in the cracking gas that can be used as fuel, it suffices to electrify only part of the furnaces to allow climate-neutral production.

Want to know more?

Project ONE: a bridge to a more sustainable future for Antwerp chemicals

|